HUGE INC. x SK-II

HUGE Inc. is a global design agency headquartered in Brooklyn, with thirteen offices worldwide. I joined their Singapore branch as an Interaction Designer on a short-term contract for SK-II, a Japanese cosmetics brand.

SK-II

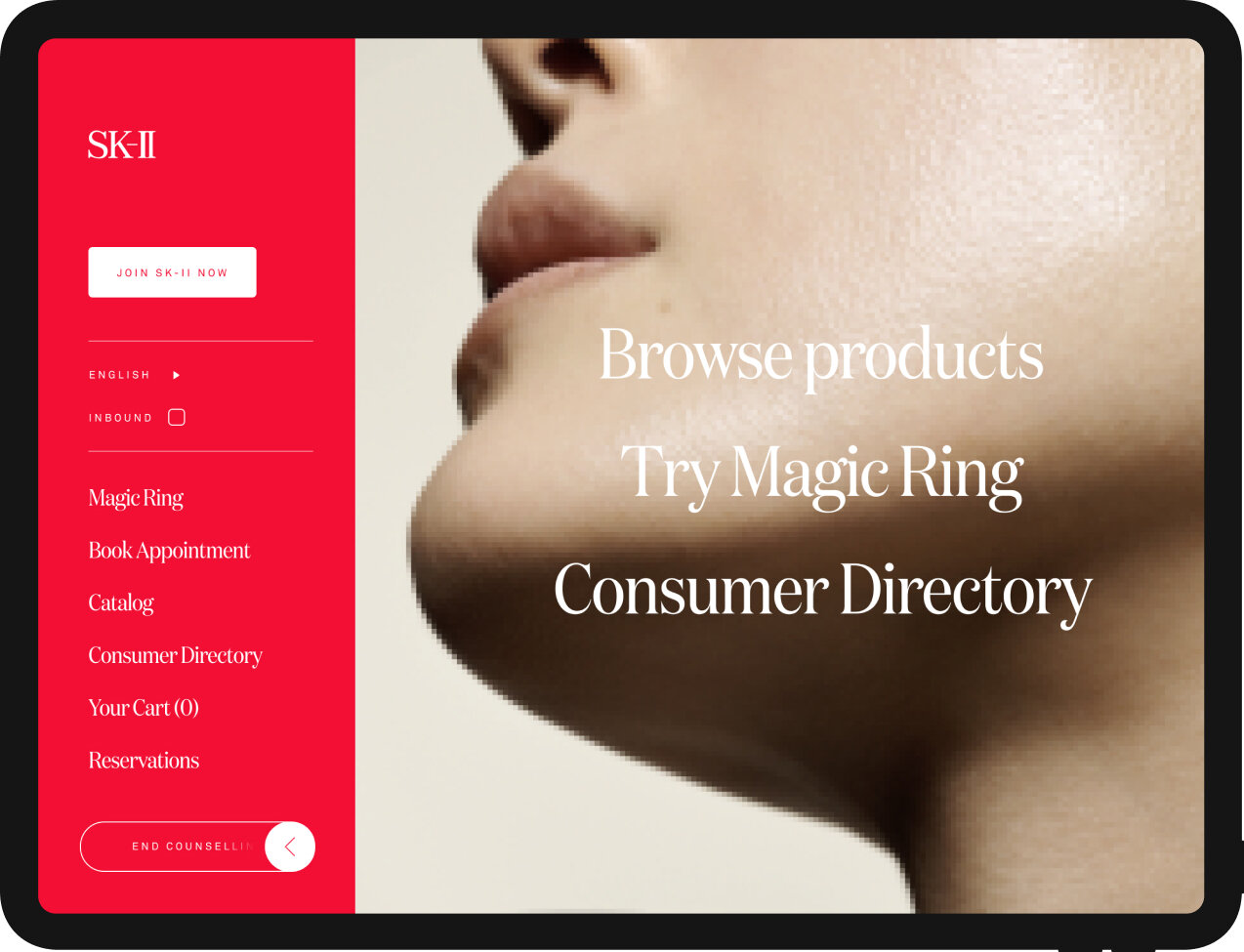

At the time, SK-II was undergoing a brand revamp to appeal to millennial and Gen-Z audiences through bold, interactive retail experiences and modernizing by moving their in-store retail operations onto an iPad app. I worked on digital products as part of this transformation.

Most notably, I designed an iPad inventory system to replace outdated paper/Excel workflows across Singapore, Japan, and China.

SK-II Business Goal

Streamline inventory management via an iPad app that works across three international markets. Move away from pen/paper, Excel, and emails to report inventory.

Research Challenges

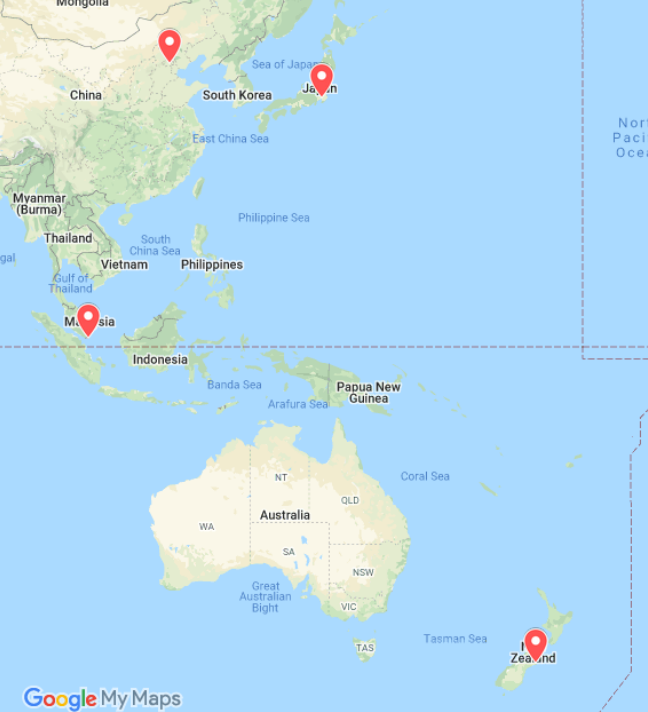

I led and contributed to UX research while coordinating across three markets, five locations, and three time zones.

Challenges:

🌍Global scope: Singapore HQ, Tokyo PM team, Beijing developers, myself in New Zealand.

😷 COVID-19 (2020): Japan was the only place the team could legally (due to shutdowns) and safely conduct remote/onsite hybrid research.

🌐 Languages: UX research in Japanese; team communication in English.

🏯 Cultural nuance: Japanese retail staff were less vocal about frustrations, requiring close observation.

UX Research Methods

UX questions provided by myself as well as colleagues

In-store observations of inventory sessions and retail operations by Japanese PM team who could travel within Japan without restriction

2-hour interviews with 5 retail staff across Japan by Japanese PM team, which was later analyzed by myself (video, screen, and audio recorded) I personally translated interviews from Japanese → English.

Store layout studies across 3 locations with Japanese PM team who could physically visit locations

I analyzed SK-II’s database and SKU categories with devs

My Key Research Findings

Retail staff across Japan, China, and Singapore took inventory monthly using paper or Excel, with results emailed to HQ. This process was:

Time-consuming: Hours of manual work for retail staff, plus additional time for HQ to collate information from multiple emails and files.

Error-prone: Manual input, duplicate records, and non-standardized discrepancy reporting led to frequent mistakes.

Frustrating: Long, unorganized product lists made items difficult to locate.

Disruptive: Inventory was conducted during store hours, meaning staff were frequently interrupted by customers.

Inconsistent: Different store layouts and storage setups resulted in SKUs being stored across multiple locations.

Non-standardized: Reports varied in format and language, making consolidation difficult.

SK-II management confirmed that these findings could be applied beyond Japan, as all retail staff worldwide received the same training as Japanese staff, regardless of market.

Jobs To Be Done

Clarifying the problem to solve through Jobs To Be Done statments.

Retail staff

When I need to complete a monthly inventory during store hours,

I want to accurately and efficiently record product counts across multiple store locations,

so that I can submit reliable data to HQ without disrupting customer service or wasting time on manual, error-prone processes.

SK-II Management

When I receive inventory data from multiple stores,

I want to get standardized, accurate, and consolidated reports,

so that I can quickly understand discrepancies and make informed decisions across all markets.

Exploring Options

I systematically explored multiple approaches to solve the Jobs To Be Done for both retail staff and management.

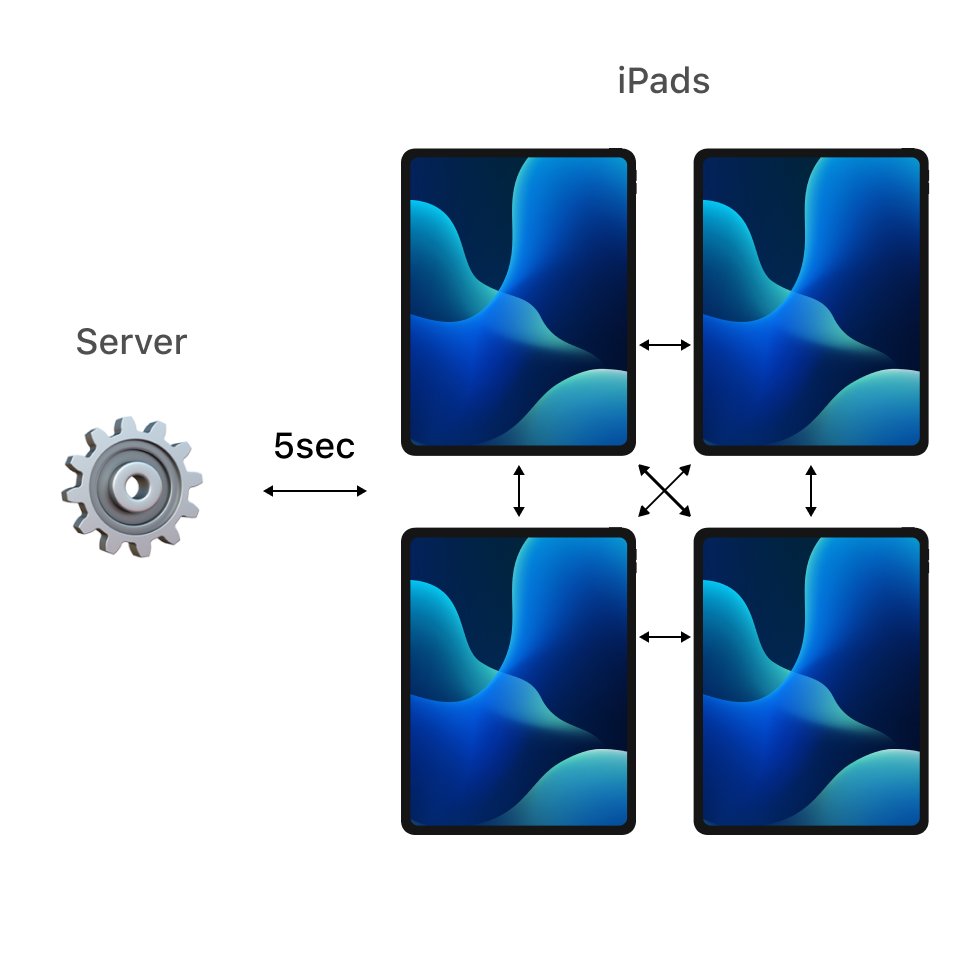

Option 1: Multi-user, real-time editing

Reasoning

Divide and conquer by allowing multiple users to do inventory simultaneously.

Obstacle

The server communicated with iPads only once every 5 seconds, meaning data was batch uploaded instead of real time.

As a result, there were 12 gaps every minute where data did not sync. During these gaps, users had no visibility into each other’s actions, creating the risk of overwriting data.

The server’s limitations became a major obstacle for every solution I explored.

Rule established

Multiple users could count inventory at the same time, but they had to be isolated from one another by SKU to avoid overwriting mistakes.

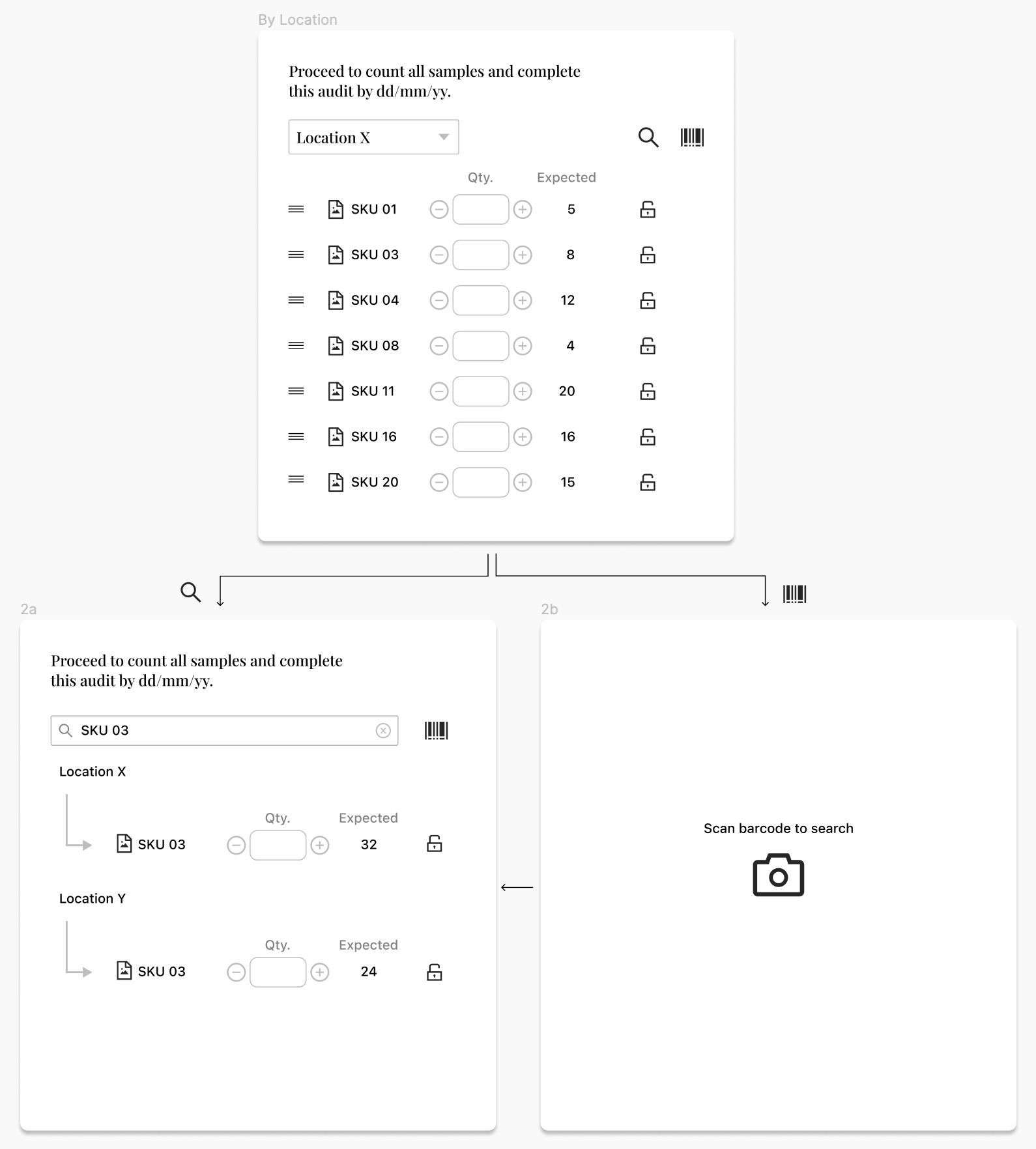

Option 2: Count by location

Reasoning

Larger retail stores often had multiple sections, so isolating users by section could allow more staff to participate in inventory.

Obstacle

SKUs appeared in multiple locations, meaning users were not isolated by SKU—the main obstacle.

Option 3: Count by product line

Reasoning

I discovered SK-II’s products could be divided into 10 non-overlapping product lines, enabling up to 10 staff to take inventory in parallel.

Obstacle

While Japan and Singapore already had databases structured this way, SK-II’s model in China was different. Restructuring their system would have required major changes across accounting, marketing, and operations. SK-II management rejected this option due to budget and timeline constraints, but I created wireframes to demonstrate it as a future-proof possibility.

Option 4: Count by category (winner)

Reasoning

SK-II’s SKUs were grouped into 3 non-overlapping categories.

Enabled up to 3 staff to work simultaneously.

Shorter, more organized lists made items easier to find.

Compatible with existing database structures across all markets.

Outcome

Reduced time, reduced errors, and worked for Japan, Singapore, and China.

Wireframe

My iterations and further improvements

Beyond the core “count by category” solution, I introduced several key improvements.

Location-based filtering

Staff could filter SKUs by store section, aligning with how they were naturally assigned store sections to manage.

Lock/unlock mechanism

Retail staff were concerned about accidentally changing SKU quantities while navigating or being interrupted by other duties during inventory. They wanted a way to “complete” a count for a SKU, but also be able to return to it later if needed.

This presented a challenge in terminology and iconography:

Using “done” implied the user was fully finishing the task.

Using “save” suggested data was being stored on the device, which was misleading.

A checkmark icon carried the same “finished” meaning as “done,” which created the wrong expectation.

The lock icon proved to be the perfect solution. Unlike the other options, it didn’t imply completion or saving. Instead, it communicated a temporary state: users understood they could lock or unlock line items, revisit them as needed, and still make changes until the inventory was officially submitted.

Reorderable SKU lists

I addressed the mismatch between digital alphabetical lists and physical store layouts by enabling staff to reorder SKUs to match the arrangement they saw in-store.

Search SKU by keyword or barcode scan

Reduced time spent finding SKUs within categories. Expanded keyword search to include staff jargon, not just official product names.

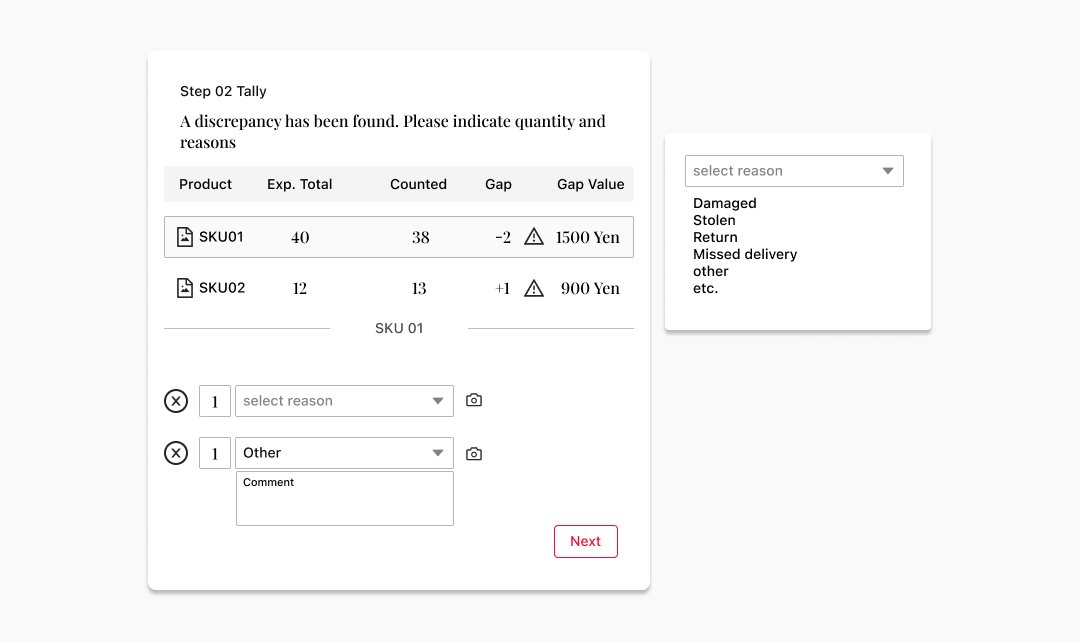

Standardized discrepancy reporting

I analyzed a year’s worth of Excel discrepancy logs to:

Identify variations of the same reason (e.g., “stolen,” “shoplifting,” “item stolen”).

Create a standardized dropdown list of common reasons (e.g., theft, damage, misplaced stock).

Save staff time and give HQ cleaner, consistent data.

Outcome of my UX contributions

My UX contributions directly:

Developed an inventory management system for three international markets.

Reduced inventory time by enabling up to 3 staff to work in parallel.

Improved accuracy by introducing category-based counting, standardized reporting, and digitized workflows.

Increased usability with features like reordering lists, lock/unlock, and barcode search.

Bridged cultural and linguistic gaps by conducting and translating Japanese research into actionable insights for a global team.

Here are other features I had to think of for inventory:

SKU is added/discontinued

User tries to add an existing SKU

SKU is found in a new location

Inventory count is paused/resumed

Location is added/removed

Location name is edited

Store layout changes

Beyond the inventory project, I also delivered UX/UI improvements for:

Web/iPad navigation menus

On-screen keyboard optimization

Search keyword improvements

Clearer calendar legends for staff scheduling

Onboarding flow for SK-II’s loyalty program

Account connection UX for LINE (popular chat app in Asia)

Reflection

This project taught me how to design within real-world constraints of servers, budgets, and legacy systems. While I often had to adapt the user experience to technical limitations, I still delivered solutions that made staff workflows faster, simpler, and less error-prone.

For me, the challenge was like solving a UX puzzle: balancing user needs, business constraints, and technical feasibility—while ensuring SK-II’s retail staff had tools that actually supported their day-to-day work.